"Principles of Crimping Technology - Compendium" is the harness makers reference book about cable connections

Everything on the subject of crimping is explained illustratively and in detail. From cutting cables to stripping to crimping. From working with hand tools to fully automatic machines. From the preparation to the testing of crimp connections. Problems and errors that may occur and how to solve or avoid them. We look at the different types of crimp terminals and their characteristics.

We explore current industry standards and explain ways how to achieve optimum quality for your own applications.

Contents of the reference book "Principles of Crimping Technology - Compendium"

- Introduction: the technologies in cable processing

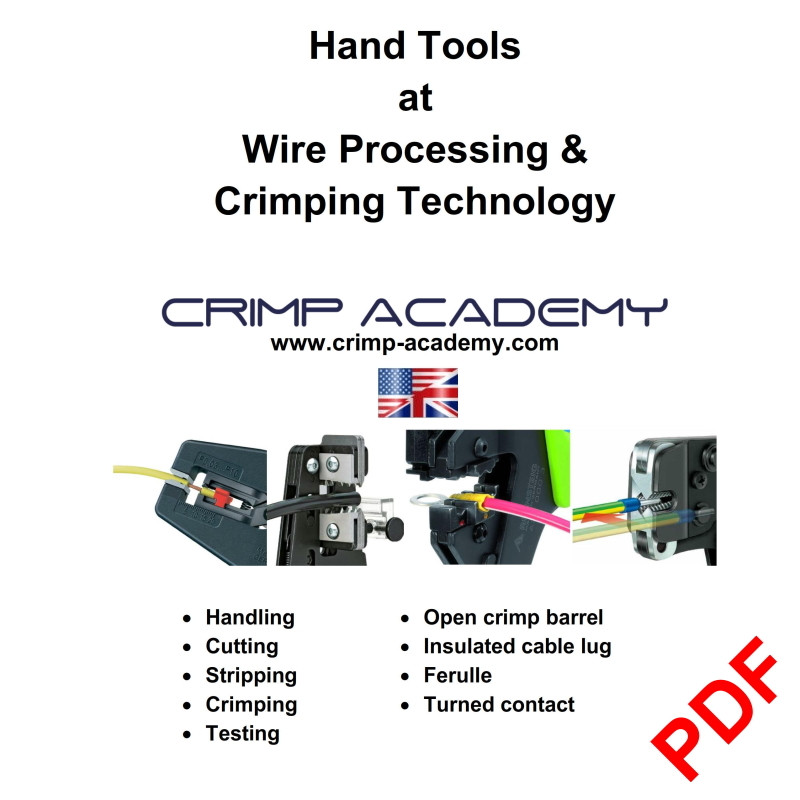

- The conductor: handling, preparation, cutting, dismantling, stripping

- Crimping: the open crimp barrel

- Test methods and application

- Machine technology

- Crimping applicators (MQC) - Open crimp barrel

- Hand tools in wire processing - cutting & stripping

- Hand crimping tools: processing of open crimp barrels.

- The closed crimp barrel

- Wire end ferrules

- Turned contacts - four indent crimp

- Insulated cable lugs

- Cable lugs & crimp connectors

- Splicing technology

- Assembly & disassembly of crimp contacts

- Crimping technology - process instructions

- Getting a grip on crimp quality - How to start

Also take a look at the training tool associated with this topic Training module: „Principles of Crimping Technology”.

Important: All information in this documentation is either excerpts from designated standards or the result of practical tests and empirical values and does not claim to be complete. All information is without guarantee and does not relieve the user of his own responsibility and duty of care towards his applications! The illustrated machines and production equipment serve to better illustrate the individual topics and are not to be understood as a purchase recommendation! Any questions? Send us an e-mail!

You have missed a topic or need more information, graphics or animations on a certain topic? Write us an e-mail!

| Publication type: PDF Download | Target Group: All |