| Type | Online Seminar | Duration | 3 - 3.5 hours |

| Date | By arrangement or training schedule | Price | 360 € (max. 5 participants) |

| Target Group | All, especially for the areas: Setup & Maintenance | Production Control, Incoming Goods | QA/QM |

Course Content

This course provides detailed information on the correct use of hand tools in wire harnessing.

Basics

- The philosophy of hand tools

- Requirements and limitations of hand tools in cable assembly

- Fields of application

- Achievable quality standards

- Special inspection requirements when using hand tools

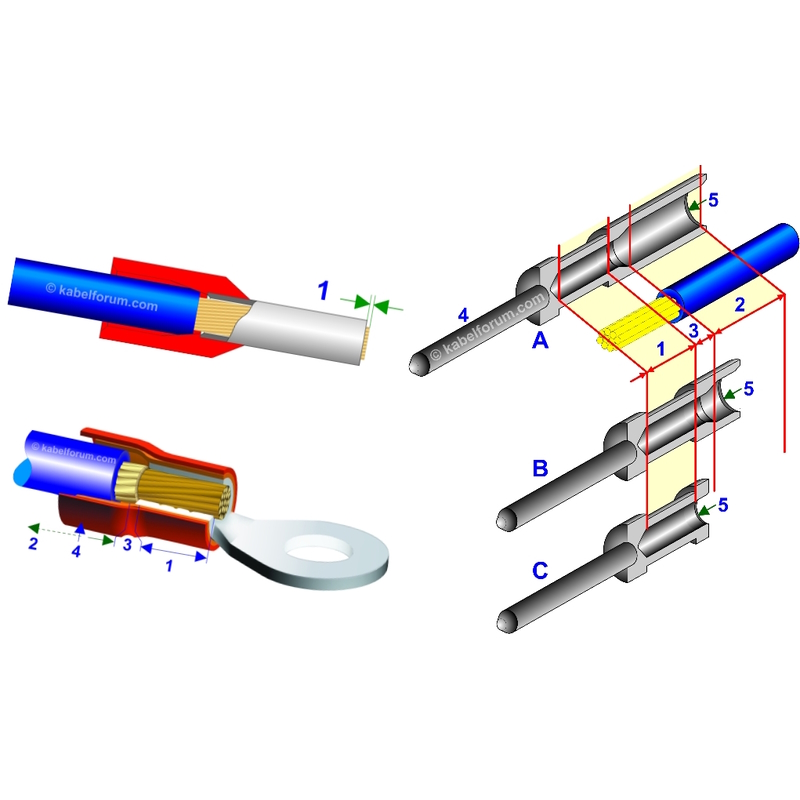

Conductor preparation - cutting & stripping

- Quality requirements for tools

- Cutting: Error detection and error prevention

- Stripping: Error detection and error prevention

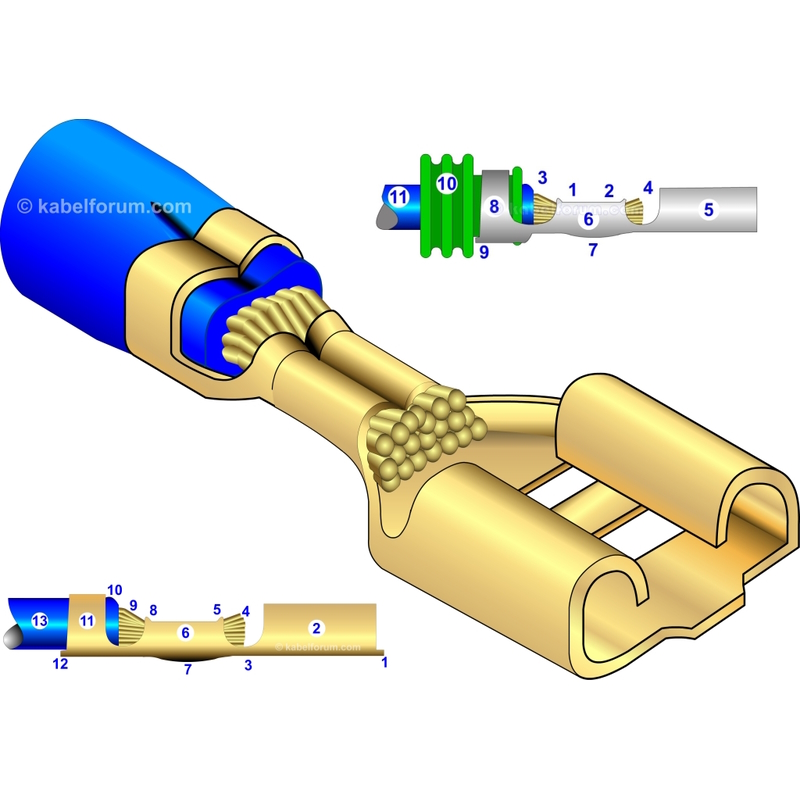

The hand crimping tool

- Types and designs

- Functions and design

- Quality requirements for the hand crimping tool

- Assignment of wire and crimp contact to the crimp dies

- Sources of error and error prevention

- Processing of open crimp barrel contacts

- Processing of closed crimp barrel contacts

- Crimping of large cross-sections

- Preparation of crimp connections

- Rework and repair of faulty crimp connections